PRODUCTS

White UV Resistant PE Sheet Manufacturer

Category:

HDPE Products

keywords :

HDPE Products

Product Introduction

HDPE board (high-density polyethylene board) is a material widely used in industry and daily life. It is mainly made of high-density polyethylene and has excellent corrosion resistance, wear resistance and impact resistance. HDPE board is lightweight and has good UV resistance. It can be used for a long time in outdoor environments without degradation. In addition, the surface of HDPE board is smooth and easy to clean. It is often used in food processing and medical equipment and other places with high hygiene requirements.

HDPE board has various functions. In addition to being used as a building material, it can also be used to make various containers, pipes, partitions and protective facilities. Its superior physical properties make it widely used in water conservancy projects, chemical storage, agriculture and other fields. Especially in agriculture, HDPE board is often used for waterproofing and isolation of greenhouses, water storage tanks and farms to help improve production efficiency.

When using HDPE board, there are several precautions that need special attention. First, due to the large thermal expansion coefficient of HDPE board, it may deform in a high temperature environment, so a certain expansion joint must be left during installation. Secondly, try to avoid placing it in a strong acid or alkali environment to avoid affecting its service life. In addition, although HDPE board is impact-resistant, it may still crack under high-intensity impact, so it should be treated with care during transportation and use. Finally, try to choose HDPE board produced by regular manufacturers to ensure that its quality and performance meet the standards, thereby ensuring safety and effectiveness in use.

| Category | Item | Typical Value | Unit | Description |

| Basic Properties | Material | High-Density Polyethylene (HDPE) | - | Thermoplastic engineering plastic polymerized from ethylene monomers |

| Density | 0.941–0.965 | g/cm³ | Lighter than water; higher density indicates higher crystallinity, hardness, and rigidity | |

| Color | White, Black (common) | - | Other colors can be customized (advance notice required) | |

| Dimensions (Thickness×Width×Length) | 1–200mm×1000–2000mm×2000–6000mm | mm | Standard sizes; customized dimensions available (confirm with suppliers) | |

| Mechanical Properties | Tensile Strength (Yield) | ≥22 | MPa | Resistance to tensile fracture; higher values indicate stronger anti-deformation capability |

| Elongation at Break | ≥350 | % | Maximum elongation before fracture; HDPE’s excellent toughness suits impact-resistant scenarios | |

| Flexural Strength | ≥25 | MPa | Resistance to bending deformation | |

| Hardness (Shore D) | 60–70 | - | Hardness increases with density, suitable for different load requirements | |

| Water Absorption | ≤0.01 | % | Virtually water-insoluble, suitable for humid environments | |

| Chemical Properties | Corrosion Resistance | Excellent | - | Resistant to acids, alkalis, salt solutions, and most organic solvents (e.g., alcohol, gasoline); not resistant to strong oxidizers (e.g., concentrated nitric acid) |

| Solvent Resistance | Excellent | - | Insoluble in most solvents at room temperature | |

| Weather Resistance | Moderate (with anti-aging agents) | - | For long-term outdoor use, UV absorbers or carbon black are recommended to enhance weather resistance | |

| Thermal Properties | Melting Point Range | 125–135 | ℃ | Better heat resistance than LDPE, lower than PP |

| Continuous Service Temperature | -40 to 80 | ℃ | Does not embrittle at low temperatures (excellent low-temperature resistance); significant strength decline at high temperatures | |

| Heat Deflection Temperature (0.45MPa) | ≥70 | ℃ | Heat resistance under load | |

| Coefficient of Linear Expansion | (10–13)×10⁻⁵ | /℃ | Moderate dimensional stability with temperature changes; expansion gaps should be 预留 (reserved) | |

| Processing Properties | Molding Methods | Extrusion, Injection Molding, Machining | - | Can be thermally formed or mechanically processed (drilling, cutting, welding) |

| Weldability | Good (hot melt welding, electrofusion welding) | - | Same-material welding allows splicing with strength close to the base material | |

| Surface Treatment | Difficult to bond (requires flame treatment or primer) | - | Inert surface; special treatment needed before adhesion | |

| Application Fields | Typical Uses | Chemical containers, water treatment equipment, wear-resistant linings, food-grade pallets, packaging materials, cushion plates, etc. | - | Widely used for corrosion resistance, wear resistance, and low-temperature tolerance |

| Standards | Domestic Standards | GB/T 11116-1989, GB/T 4454-2008 | - | Standards for board dimensions and performance testing |

| International Standards | ASTM D4020, ISO 4726 | - | Reference for export products |

Factory inventory

Customer Service Praise

Packaging and shipping

Application Examples

The products are widely used in ports, electric power, petrochemical, laboratory, medical, coal, food, machinery manufacturing and transmission industries.

Fender Panel

Ground protection pad (roadbed)

Coal Bunker Lining

Football Training Board

PP water tank

Ultra-high Processing Parts

Outrigger Pads

Anti-ice Board

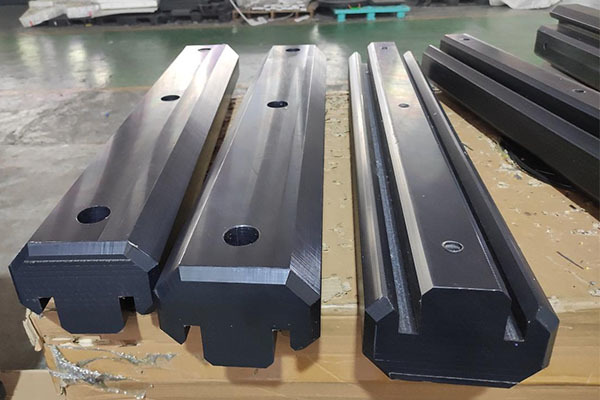

Sleeper

Frequently Asked Questions

— Does it support prepayment of deposit?

Sure, the specific amount will be negotiated based on the product and value of the goods

— Can we conduct an on-site inspection at the factory?

Of course, we always welcome overseas friends to conduct on-site inspections and taste local cuisine

— Does the company provide after-sales service?

It is necessary. We welcome customers to raise questions at any time, provide 24-hour online answers, discuss cooperation processes, product usage, etc

— Which port does the goods export from?

Generally, it is Tianjin Port, Qingdao Port, Shanghai Port, and can also be shipped from ports designated by customers

— Are you a factory or a trading company?

We are a wear-resistant material production factory with a large production plant in Ningjin, China

— Once the products received by customer were found not comply with the products or contract demands, what will you do?

We will compensate the customer for all the loss without any hesitation.

GET A FREE QUOTE

RELATED PRODUCTS