PRODUCTS

Customized Processing PP Water Tank Manufacturer

Category:

PP Water Tank

keywords :

PP Water Tank

Product Introduction

PP water tank, PP water tank is mainly made of polypropylene (PP) material, which has excellent corrosion resistance, high temperature resistance and aging resistance, so that it can still maintain good performance in various harsh environments. Its main function is to store and transport liquids, and it is widely used in many fields such as industry, agriculture, chemical industry, food, etc. In agriculture, PP water tanks are often used for irrigation and water storage, helping farmers improve the utilization efficiency of water resources; in industry, they are used as storage containers for chemicals to ensure safety and environmental protection.

When using PP water tanks, users need to pay attention to some matters to ensure their service life and safety. First, avoid placing the water tank in direct sunlight or high temperature environment to avoid affecting the stability of the material. Secondly, regularly check the sealing of the water tank to prevent leakage and pollution. In addition, the inside of the water tank should be kept clean and cleaned regularly to prevent bacterial growth and deterioration of water quality.

When choosing a PP water tank, the appropriate model and capacity should be selected according to the specific purpose and needs to ensure that it can effectively meet the use requirements. In short, PP water tanks have become important equipment for modern water storage and liquid transportation with their superior performance and diverse uses. Reasonable use and maintenance will greatly extend their service life and improve work efficiency.

Product Parameters

| Category | Item | Typical Value/Description |

| Basic Information | Material | Polypropylene (PP), usually food-grade PP compliant with FDA or relevant food safety standards |

| Structure | One-piece molding or assembled (welded) | |

| Shape | Circular, rectangular, cylindrical, custom shapes available | |

| Dimensions | Capacity | 50L - 50,000L (or more, customizable) |

| Diameter (for circular tanks) | 300mm - 3000mm | |

| Height | 400mm - 5000mm | |

| Wall Thickness | 3mm - 20mm (thicker for larger capacities and higher pressures) | |

| Material Properties | Density | 0.90 - 0.91 g/cm³ |

| Melting Point | 165 - 170 ℃ | |

| Continuous Service Temperature | -20℃ to 100℃ | |

| Chemical Resistance | Excellent resistance to most acids, alkalis, and common chemicals; not resistant to strong oxidizers | |

| Performance Indicators | Pressure Resistance | Designed for normal atmospheric pressure; some models can withstand low - pressure applications |

| Leak - proof Performance | High - precision welding or molding to ensure no leakage | |

| UV Resistance | Standard models have basic UV resistance; can be enhanced with additives for outdoor use | |

| Impact Resistance | Good impact resistance at normal temperatures; may decrease in low - temperature environments | |

| Accessories | Inlet/Outlet Fittings | Standard sizes (DN15 - DN100), materials: PP, PVC, stainless steel |

| Manhole Cover | Available for large - capacity tanks, diameter usually 400mm - 600mm | |

| Float Valve Mounting | Optional for automatic water level control | |

| Installation & Use | Installation Method | Ground - mounted, supported by flat and stable surfaces; not suitable for suspended installation |

| Usage Environment | Indoor and outdoor use; avoid direct long - term exposure to high - intensity sunlight without protection | |

| Standards | International Standards | FDA (for food - contact applications), ISO 19223 (related to plastics) |

| Domestic Standards (China) | GB/T 12024 - 2005, GB/T 18442 - 2019 | |

| Customization Options | Color | White, black, blue, or customized colors |

| Special Features | Anti - static treatment, anti - corrosion coating, customized inlet/outlet positions |

Factory inventory

Customer Service Praise

Packaging and shipping

Application Examples

The products are widely used in ports, electric power, petrochemical, laboratory, medical, coal, food, machinery manufacturing and transmission industries.

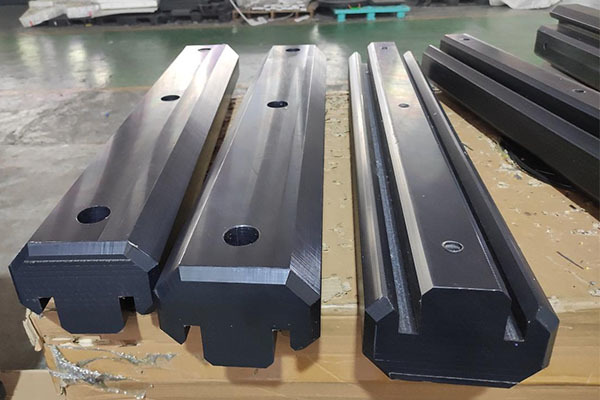

Fender Panel

Ground protection pad (roadbed)

Coal Bunker Lining

Football Training Board

PP water tank

Ultra-high Processing Parts

Outrigger Pads

Anti-ice Board

Sleeper

Frequently Asked Questions

— Does it support prepayment of deposit?

Sure, the specific amount will be negotiated based on the product and value of the goods

— Can we conduct an on-site inspection at the factory?

Of course, we always welcome overseas friends to conduct on-site inspections and taste local cuisine

— Does the company provide after-sales service?

It is necessary. We welcome customers to raise questions at any time, provide 24-hour online answers, discuss cooperation processes, product usage, etc

— Which port does the goods export from?

Generally, it is Tianjin Port, Qingdao Port, Shanghai Port, and can also be shipped from ports designated by customers

— Are you a factory or a trading company?

We are a wear-resistant material production factory with a large production plant in Ningjin, China

— Once the products received by customer were found not comply with the products or contract demands, what will you do?

We will compensate the customer for all the loss without any hesitation.

GET A FREE QUOTE

RELATED PRODUCTS