PRODUCTS

Polypropylene Food Grade PP Sheet

Category:

PP Board

keywords :

PP Board

Product Introduction

PP board, also known as polypropylene board, is a plastic board made of polypropylene material. It is widely used in various fields due to its excellent physical and chemical properties. The main features of PP board are light weight, corrosion resistance, impact resistance, good insulation, and high tensile strength and rigidity.

In addition, PP board also has good heat resistance and chemical resistance, can be used at higher temperatures, and is not easily corroded by acids and alkalis. Due to these advantages, PP board is widely used in billboards, packaging, mechanical equipment shields, chemical equipment protection, household goods, and electronic product shells.

When using PP board, there are some precautions that need special attention. First, try to avoid exposing PP board to strong ultraviolet rays. Long-term ultraviolet radiation may cause its surface aging and color fading. Secondly, when PP board is used in a high temperature environment, pay attention to temperature control to avoid exceeding its heat resistance limit to avoid deformation.

In addition, although PP board has good impact resistance, it still needs to be careful under high impact to prevent breakage. Finally, when processing and cutting PP board, it is recommended to use professional tools and equipment to ensure the smoothness and flatness of the cutting edge, thereby improving its use effect and aesthetics. Through reasonable use and maintenance, PP board can play its best performance and meet the needs of different fields.

| Category | Item | Typical Value | Unit | Description |

| Basic Properties | Material | Polypropylene (PP) | - | Thermoplastic polymer derived from propylene monomers |

| Density | 0.91 - 0.93 | g/cm³ | Lighter than water; lower density compared to HDPE | |

| Appearance | Translucent to opaque | - | Natural color is white, can be customized | |

| Crystal Structure | Isotactic (most common) | - | High crystallinity for enhanced mechanical properties | |

| Mechanical Properties | Tensile Strength (Yield) | 30 - 40 | MPa | Stronger than LDPE, suitable for structural applications |

| Elongation at Break | ≥300 | % | Good ductility, though lower than some PE grades | |

| Flexural Modulus | 1200 - 1800 | MPa | Indicates stiffness; higher values mean better resistance to bending | |

| Hardness (Rockwell R) | 80 - 100 | - | Harder than PE, suitable for wear-resistant uses | |

| Impact Strength (Notched Izod) | 2 - 6 | kJ/m² | Varies with temperature; may require additives for cold resistance | |

| Chemical Properties | Chemical Resistance | Excellent | - | Resistant to most acids, alkalis, and organic solvents, except strong oxidizers |

| Solvent Resistance | Good | - | Insoluble in common solvents at room temperature, but may swell in some | |

| Hygroscopicity | ≤0.01 | % | Negligible water absorption, suitable for humid environments | |

| Thermal Properties | Melting Point | 165 - 170 | ℃ | Higher than PE, enabling better heat resistance |

| Continuous Service Temperature | -20 to 100 | ℃ | Can maintain performance in a wide temperature range, but brittle below -20℃ | |

| Heat Deflection Temperature (1.82MPa) | 50 - 70 | ℃ | Lower under load; reinforcing fillers can improve this value | |

| Coefficient of Thermal Expansion | (6 - 10) × 10⁻⁵ | /℃ | Higher than metals, expansion joints may be needed in large installations | |

| Processing Properties | Molding Methods | Injection molding, Extrusion, Thermoforming | - | Widely processed using common plastic fabrication techniques |

| Welding Methods | Hot air welding, Extrusion welding, Ultrasonic welding | - | Weldable, but requires proper surface preparation and technique | |

| Surface Adhesion | Poor | - | Surface treatment (flame treatment, corona treatment) needed for bonding | |

| Electrical Properties | Dielectric Strength | 25 - 35 | kV/mm | Excellent insulator, suitable for electrical applications |

| Volume Resistivity | ≥10¹⁶ | Ω·cm | High resistivity maintains electrical isolation | |

| Applications | Typical Uses | Chemical tanks, Food containers, Medical devices, Electrical enclosures, Automotive parts | - | Leveraging its chemical resistance, heat resistance, and hygiene properties |

| Standards | International | ASTM D4101, ISO 19223 | - | Commonly referenced for quality control and testing |

| Domestic (China) | GB/T 12024 - 2005, GB/T 18442 - 2019 | - | Chinese standards for PP products |

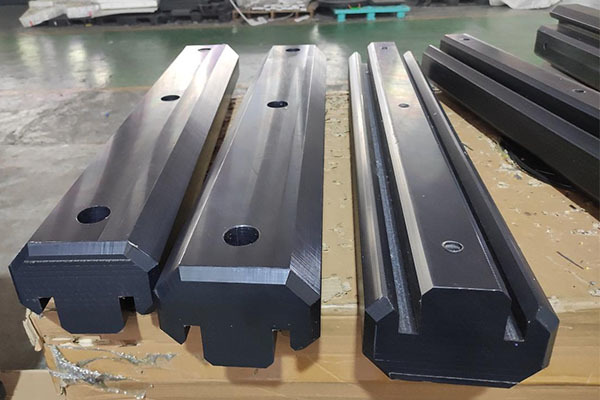

Factory inventory

Customer Service Praise

Packaging and shipping

Application Examples

The products are widely used in ports, electric power, petrochemical, laboratory, medical, coal, food, machinery manufacturing and transmission industries.

Fender Panel

Ground protection pad (roadbed)

Coal Bunker Lining

Football Training Board

PP water tank

Ultra-high Processing Parts

Outrigger Pads

Anti-ice Board

Sleeper

Frequently Asked Questions

— Does it support prepayment of deposit?

Sure, the specific amount will be negotiated based on the product and value of the goods

— Can we conduct an on-site inspection at the factory?

Of course, we always welcome overseas friends to conduct on-site inspections and taste local cuisine

— Does the company provide after-sales service?

It is necessary. We welcome customers to raise questions at any time, provide 24-hour online answers, discuss cooperation processes, product usage, etc

— Which port does the goods export from?

Generally, it is Tianjin Port, Qingdao Port, Shanghai Port, and can also be shipped from ports designated by customers

— Are you a factory or a trading company?

We are a wear-resistant material production factory with a large production plant in Ningjin, China

— Once the products received by customer were found not comply with the products or contract demands, what will you do?

We will compensate the customer for all the loss without any hesitation.

GET A FREE QUOTE

RELATED PRODUCTS