PRODUCTS

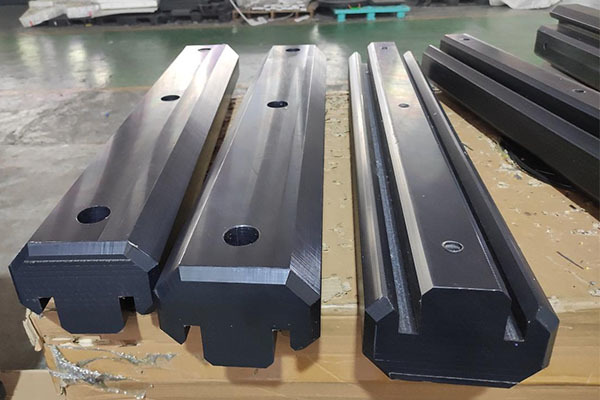

No slipping on rainy or snowy days Single sided anti slip pattern substrate

Category:

Road Base

keywords :

Road Base

Product Introduction

Heavy-duty (molded) roadbed is a high-strength, high-wear-resistant engineering material, mainly made of composite materials such as polymer-modified cement and glass fiber. Its main function is to provide solid support for infrastructure such as roads and bridges, enhance the bearing capacity of the road surface, and ensure driving safety. Heavy-duty roadbed can effectively resist compression, tension and shear force during construction, and has excellent weather resistance and anti-aging properties, so it can maintain its stability and reliability in various harsh environments.

Heavy-duty roadbed has a wide range of uses. In addition to being used in transportation infrastructure such as roads, railways, and airports, it can also be used for ground paving in industrial plants, warehousing and logistics centers, and large-scale event venues, and even in some special engineering projects, such as tunnels and mines. Due to its unique molding process, heavy-duty roadbed can be customized according to different needs to meet the special requirements of different projects.

When using heavy-duty roadbed, you need to pay attention to several aspects.

First, ensure that the foundation is fully treated before installation to ensure the flatness and bearing capacity of the foundation;

Second, be careful during transportation and handling to avoid collisions and scratches to avoid affecting its performance;

Finally, regularly inspect and maintain the roadbed, and promptly handle cracks or damage to ensure its long-term and stable use.

Through reasonable use and maintenance, heavy-duty roadbed will provide strong protection for the safety and durability of infrastructure.

Product Parameters

| Category | Item | Typical Value/Description |

| Basic Information | Material | Ultra - High Molecular Weight Polyethylene (UHMWPE), Fiberglass - Reinforced Polymer (FRP), or High - Strength Composite Materials |

| Manufacturing Process | Compression Molding | |

| Dimensions | Thickness | 20 - 50 mm |

| Length | 3000 - 6000 mm | |

| Width | 2000 - 3000 mm | |

| Material Properties | Density | UHMWPE: 0.93 - 0.94 g/cm³ FRP: 1.5 - 2.0 g/cm³ |

| Tensile Strength | UHMWPE: ≥35 MPa FRP: ≥200 MPa | |

| Flexural Strength | UHMWPE: ≥40 MPa FRP: ≥300 MPa | |

| Impact Resistance | Excellent, capable of withstanding heavy impacts from large machinery | |

| Mechanical Properties | Load - Bearing Capacity | 50 - 200 tons (suitable for heavy - duty vehicles and equipment in construction, mining, etc.) |

| Hardness | Shore D 60 - 85 (UHMWPE), High Hardness for FRP | |

| Anti - Slip Surface | Deep - Grooved or Textured Surface, providing strong traction even in harsh conditions | |

| Environmental Properties | Temperature Resistance | -40°C to 80°C, maintaining stable performance in extreme temperatures |

| Chemical Resistance | Highly resistant to acids, alkalis, and common industrial chemicals | |

| Abrasion Resistance | Exceptional abrasion resistance, suitable for long - term use in high - traffic areas | |

| Installation & Use | Connection Method | Heavy - Duty Interlocking Mechanisms, Bolt - on or Pin - and - Sleeve Connectors |

| Ease of Handling | Require machinery (e.g., forklifts) for installation and relocation due to high weight | |

| Reusability | Can be reused multiple times, with minimal wear and tear | |

| Standards | International Standards | ASTM D4020 (for UHMWPE), ASTM D790 (for flexural properties of plastics), ISO 527 (tensile testing) |

| Domestic Standards (China) | GB/T 1843 - 2008 (impact resistance testing), Relevant Construction and Mining Equipment Standards |

Factory inventory

Packaging and shipping

Application Examples

The products are widely used in ports, electric power, petrochemical, laboratory, medical, coal, food, machinery manufacturing and transmission industries.

Fender Panel

Ground protection pad (roadbed)

Coal Bunker Lining

Football Training Board

PP water tank

Ultra-high Processing Parts

Outrigger Pads

Anti-ice Board

Sleeper

Frequently Asked Questions

— Does it support prepayment of deposit?

Sure, the specific amount will be negotiated based on the product and value of the goods

— Can we conduct an on-site inspection at the factory?

Of course, we always welcome overseas friends to conduct on-site inspections and taste local cuisine

— Does the company provide after-sales service?

It is necessary. We welcome customers to raise questions at any time, provide 24-hour online answers, discuss cooperation processes, product usage, etc

— Which port does the goods export from?

Generally, it is Tianjin Port, Qingdao Port, Shanghai Port, and can also be shipped from ports designated by customers

— Are you a factory or a trading company?

We are a wear-resistant material production factory with a large production plant in Ningjin, China

— Once the products received by customer were found not comply with the products or contract demands, what will you do?

We will compensate the customer for all the loss without any hesitation.

GET A FREE QUOTE

RELATED PRODUCTS