PRODUCTS

Temporary paving pad for construction site

Category:

Road Base

keywords :

Road Base

Product Introduction

Lightweight (extruded) roadbed is a modern building material widely used in the construction of roads, bridges and other infrastructure. Its main material is usually polymer materials, such as polyethylene (PE) or polypropylene (PP), which have excellent corrosion resistance, compressive strength and light weight, making the roadbed not easy to deform when carrying heavy objects.

In addition, the function of lightweight roadbed is not limited to supporting and dispersing loads, but can also effectively improve the stability of soil and reduce settlement. They are used in a wide range of applications, including but not limited to urban roads, factory warehouses, airport runways, and temporary construction sites.

When using lightweight roadbed, there are several precautions that need special attention.

First, the foundation needs to be fully inspected before construction to ensure that its bearing capacity meets the requirements. Second, during the installation process, excessive compaction should be avoided to avoid damaging the structure of the roadbed.

In addition, it is also very important to regularly check and maintain the state of the roadbed to ensure its long-term stable performance.

In the future, with the development of science and technology and the advancement of materials engineering, the performance and application range of lightweight roadbed will be further expanded, providing more efficient and environmentally friendly solutions for infrastructure construction.

Product Parameters

| Category | Item | Typical Value/Description |

| Basic Information | Material | High - Density Polyethylene (HDPE), Polypropylene (PP), or composite polymers with glass fiber/wood fiber reinforcement |

| Manufacturing Process | Extrusion molding | |

| Dimensions | Thickness | 8 - 15 mm (lightweight design for easy handling) |

| Length | 2000 - 4000 mm | |

| Width | 1000 - 2000 mm | |

| Weight per Unit Area | 8 - 15 kg/m² (varies by material and thickness) | |

| Material Properties | Density | HDPE: 0.941 - 0.965 g/cm³ PP: 0.90 - 0.91 g/cm³ Composite: 1.0 - 1.2 g/cm³ |

| Tensile Strength | HDPE: ≥22 MPa PP: 30 - 40 MPa Composite: ≥45 MPa | |

| Flexural Strength | HDPE: ≥25 MPa PP: 40 - 50 MPa Composite: ≥60 MPa | |

| Impact Resistance | Good shock absorption; can withstand sudden loads from equipment movement | |

| Mechanical Properties | Load - Bearing Capacity | 5 - 20 tons (depends on thickness, material, and ground conditions) |

| Anti - Slip Surface | Embossed, textured, or grooved surface for enhanced traction in wet, muddy, or icy conditions | |

| Bending Resistance | Maintains structural integrity under bending stress, suitable for uneven terrains | |

| Environmental Properties | Temperature Resistance | -40°C to 80°C (HDPE and PP - based panels), ensuring performance in various climates |

| Chemical Resistance | Resistant to common chemicals, solvents, and moisture; suitable for outdoor and industrial use | |

| UV Resistance | UV - stabilized additives to prevent degradation from long - term sunlight exposure | |

| Installation & Use | Connection System | Interlocking tabs, snap - fit joints, or bolt - on connectors for quick assembly and disassembly |

| Reusability | Can be reused multiple times; recyclable at end - of - life | |

| Ease of Transport | Lightweight design allows for manual handling or transportation with standard equipment | |

| Standards | International Standards | ASTM D4020 (for polyethylene), ASTM D4101 (for polypropylene), EN 13161 (geosynthetic materials) |

| Domestic Standards (China) | GB/T 11116 - 1989 (HDPE), GB/T 12024 - 2005 (PP - related) |

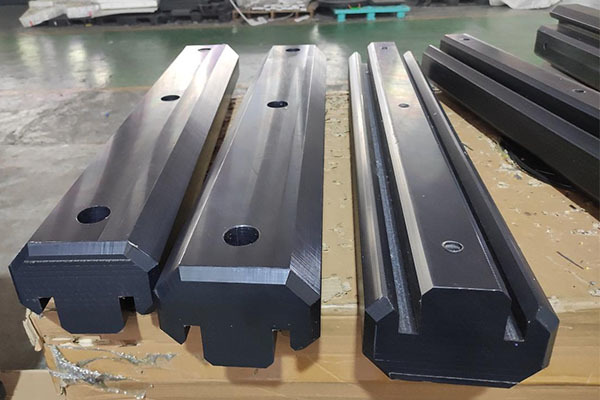

Factory inventory

Packaging and shipping

Application Examples

The products are widely used in ports, electric power, petrochemical, laboratory, medical, coal, food, machinery manufacturing and transmission industries.

Fender Panel

Ground protection pad (roadbed)

Coal Bunker Lining

Football Training Board

PP water tank

Ultra-high Processing Parts

Outrigger Pads

Anti-ice Board

Sleeper

Frequently Asked Questions

— Does it support prepayment of deposit?

Sure, the specific amount will be negotiated based on the product and value of the goods

— Can we conduct an on-site inspection at the factory?

Of course, we always welcome overseas friends to conduct on-site inspections and taste local cuisine

— Does the company provide after-sales service?

It is necessary. We welcome customers to raise questions at any time, provide 24-hour online answers, discuss cooperation processes, product usage, etc

— Which port does the goods export from?

Generally, it is Tianjin Port, Qingdao Port, Shanghai Port, and can also be shipped from ports designated by customers

— Are you a factory or a trading company?

We are a wear-resistant material production factory with a large production plant in Ningjin, China

— Once the products received by customer were found not comply with the products or contract demands, what will you do?

We will compensate the customer for all the loss without any hesitation.

GET A FREE QUOTE

RELATED PRODUCTS